Bottle Rocket

| Race Order |

Entry # | Driver Name | Car Name | Mass (grams) |

Length (inches) |

Width (inches) |

Height (inches) |

Distance Traveled (feet) |

Running Time (seconds) |

Awards |

| 12 | 30 | Mike Blakely | Bottle Rocket | 394 | 72 | 6 | 4.3 | 47.92 | 6.16 | 3rd Farthest Distance & Most Creative & Largest |

Balloon car designer Mike Blakely writes:

- Design approach taken – explain how it worked.

This design attempted to harness as much energy as possible from the

deflating balloons by having their escaping air feed into a chamber which

would grow in volume by having a surface which moved against a load. The

work done on that moving surface by the deflating balloons was to be coupled

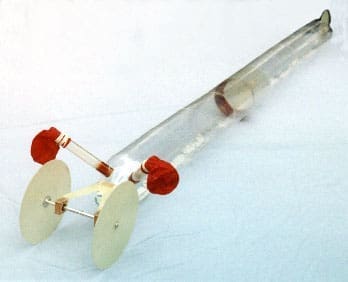

to the driving axle of the car with as little loss as practical.The moving surface took the form of a cone-shaped piston in a tube, and the

force of the piston was applied against a thin line which was wound around

the driving axle. The tube just mentioned also served as the body of the

car, with a single wheel running on a ball bearing in front and two wheels

in the rear attached to an axle which turned in two of the same ball bearings. - Unique or clever features embodied

Starting with the balloons, they were to be exhausted efficiently by

avoiding unnecessary throttling and turbulence in their outflow. To

accomplish this, large-diameter tubes (3/4 inch) were installed all the

way through the stems of the balloons to hold them open.The piston incorporated a flexible skirt of overlapping pieces of Kapton

sheet. Paper works as well but is much less durable and seemed to have more

friction against the tube. - Materials of construction (mention unique parts you used or fabricated)

The body/cylinder of the car was made from 2-liter Pepsi bottles, very

carefully

cut, fit together and taped around the circumference. The balloon exhaust

tubes

came from the remains of a fish aquarium filter. The piston is made from

.007″

epoxy-glass sheet, rolled into a cone and lap bonded with quick-setting epoxy.

A piston stabilizer ring is made from .015″ epoxy-glass and prevents the

piston

from cocking in the tube. The apex of the cone piston is slightly

truncated and

capped with a small disk of .031″ epoxy-glass; it is this disk which supports

the tensile load of the .010″-diameter fishing line which runs back and around

the rear axle.All wheels, just under 6″ diameter, are made from .031″ epoxy-glass. The rear

suspension yoke is also epoxy-glass (we love it) .045″ thick. Rear axle

bearings

are a light press fit into tapered holes in wooden pillow blocks which are

bonded

with epoxy to the yoke. The front wheel bearing is pressed into the wheel

itself.

The rear axle is made from 1/4″ aluminum rod and the wheels attach with #10-32

aluminum screws. - Reasons behind any significant design choices you had to make

One major choice was the tubing/car body diameter. Larger diameter had the

benefit

of requiring less piston travel to exhaust the balloons, but would result

in larger

piston force and would need larger wheels to keep the tube clear of the

ground.

Smaller tubing had the advantage of producing less piston force, allowing

lighter

construction of some components, but to fully utilize the air from two

balloons

the overall length of the car became unreasonable with diameters under 4

inches.

In the end, this issue was settled by the practical availability of light

tubing;

2-liter Pepsi bottles are about 4.3″ diameter and cost little. But now the

problem

of the inevitable imperfect joint between bottles, and variations in

diameter…The choice of a cone for the piston solved that problem. The thin cone

itself is

flexible and can easily be squeezed into an oval shape at its base; it

still works

fine if the tubing is far from round. But the tubing also had variations

in its

molded diameter, as much as .02″, so a simple cone could never be expected

to seal

properly along the length of the car. That was solved by making the piston

slightly

undersize and then adding a flexible skirt to follow the tubing

irregularities. The

skirt provides a positive seal in that, the more the pressure behind it,

the more the

skirt presses against the wall of the tube. The friction of the Kapton

skirt against

the plastic tubing turned out to be low so my plan to apply a thin film of

silicone

lubricant to the bore was abandoned. The piston force was already

threatening to

break the six-pound fishing line.Wheel diameter was mostly driven by the need to raise the car body off the

ground by

some safe distance, and I settled for a bit less than an inch of clearance.

Larger

diameter wheels were not used because six-inch wheels seemed more than

large enough

to travel smoothly over the course, and the car’s powered travel (while

piston is

applying torque to the axle) was already calculated to be a large figure

with respect

to the course – 110 to 120 feet depending on how well the fishing line was

wound on

the axle. With a fixed piston travel of 50″ and 1/4″ axle with small

groove to contain

the line wrapped in 5 or more layers, larger wheels to increase the travel

under power

seemed unnecessary. If the car were able to clear the narrow part of the

course and

achieve its 110 feet of powered travel, the free-running wheel bearings

were expected

to allow it to easily reach the end of the course. - Lessons learned (what you’d do differently next time)

Test, test, test because the steering (ability to run straight) needed

improvement.

That is easy to say, but the car was difficult to build to the necessary

standards and

there was very little time left, and always a chance of damage. Steering

alignment

was limited to several coasting tests, seemed OK, but was compromised by a

handling

mistake at the last moment. More tests could have revealed that weakness. - Anything else you’d like to add

Some interesting figures…

Pressure measurements were made of inflated balloons. A balloon inflating

for the first

time needed about 30 Torr for inflation. While deflating, pressure would

stay around

20 Torr. A very tired balloon deflating produced a minimum of 10 Torr.

Remember 760 Torr

is one atmosphere, 14.7 psi, so my design pressure was between 0.19 psi and

0.39 psi.The piston area is that of a 4.3″ diameter circle, 14.5 square inches, so

the force on the

piston from the above pressure is from 2.75 to 5.5 pounds. Not bad if

friction doesn’t

eat much up (it doesn’t).Piston travel is 50 inches at full pressure and is physically stopped

there. The deflating

balloons do work on the moving piston, and work = force x distance. Let’s

assume a force of

3 pounds over 50 inches of piston travel. That is 150 in.lb of work. What

can that work do?

If we ignore losses such as rolling and air resistance, we can do a simple

calculation of the

peak velocity of the car. Of course air resistance is significant with

those balloons dragged

along, but let’s ignore it because the calculations are much simpler and

the answer is more

surprising.Assume the work, 150 lb.in, is all converted to kinetic energy T, where

T=1/2 MV*2, M being

the mass of the car and V is the velocity of the car. (A full accounting

of the kinetic energy

of the car should include rotation of the wheels and axle, where T=1/2

Iw*2, I being moment of

inertia and w being angular velocity in radians per second. Again, let’s

ignore this term.)

Let’s work with pounds, inches and seconds. The car weighs 0.8 pounds, but

that is not M.

We need the M from W=MG where W is weight in pounds and G is acceleration

of gravity in

inches/second*2. We find that M = 0.8/386, or .00207 “mass units”. Now V

= [2×150/.00207]*1/2

= 380 inches/second = 31.7 feet/second. Wow! All those spectators who

were in the way should

be glad the car went into the wall instead of down the middle of the track!

MB 1/9/99